SO-101 Arm

A build-to-sim-to-real workflow: 3D printed components on my Bambu P1S, simulated in Isaac Sim, then validated on the real arm with hands-on testing.

Overview

Build → simulate → test

This project is awesome, it was good experience working with inverse kinematics initially, using visual detection,and using isaac sim. Ultimately though I am just a sucker for robotic arms adn end effectors.

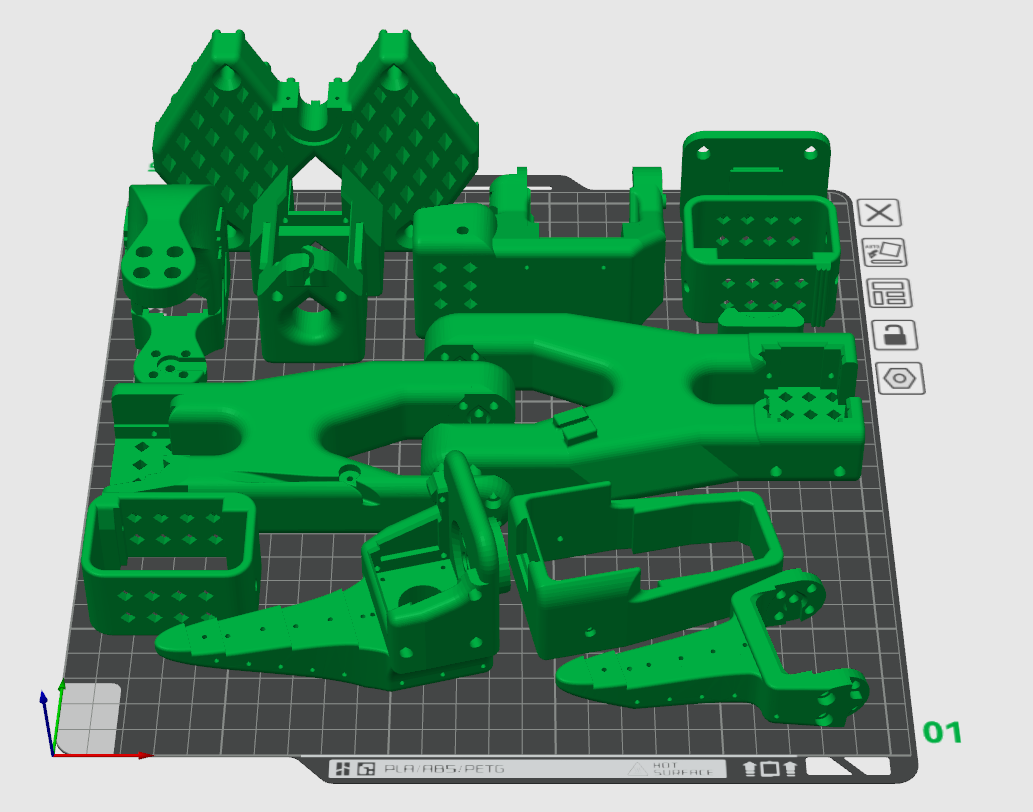

3D Printing on the Bambu P1S

Print workflow

I printed the SO-101 parts on my Bambu P1S, its always super easy, quick and reliable.

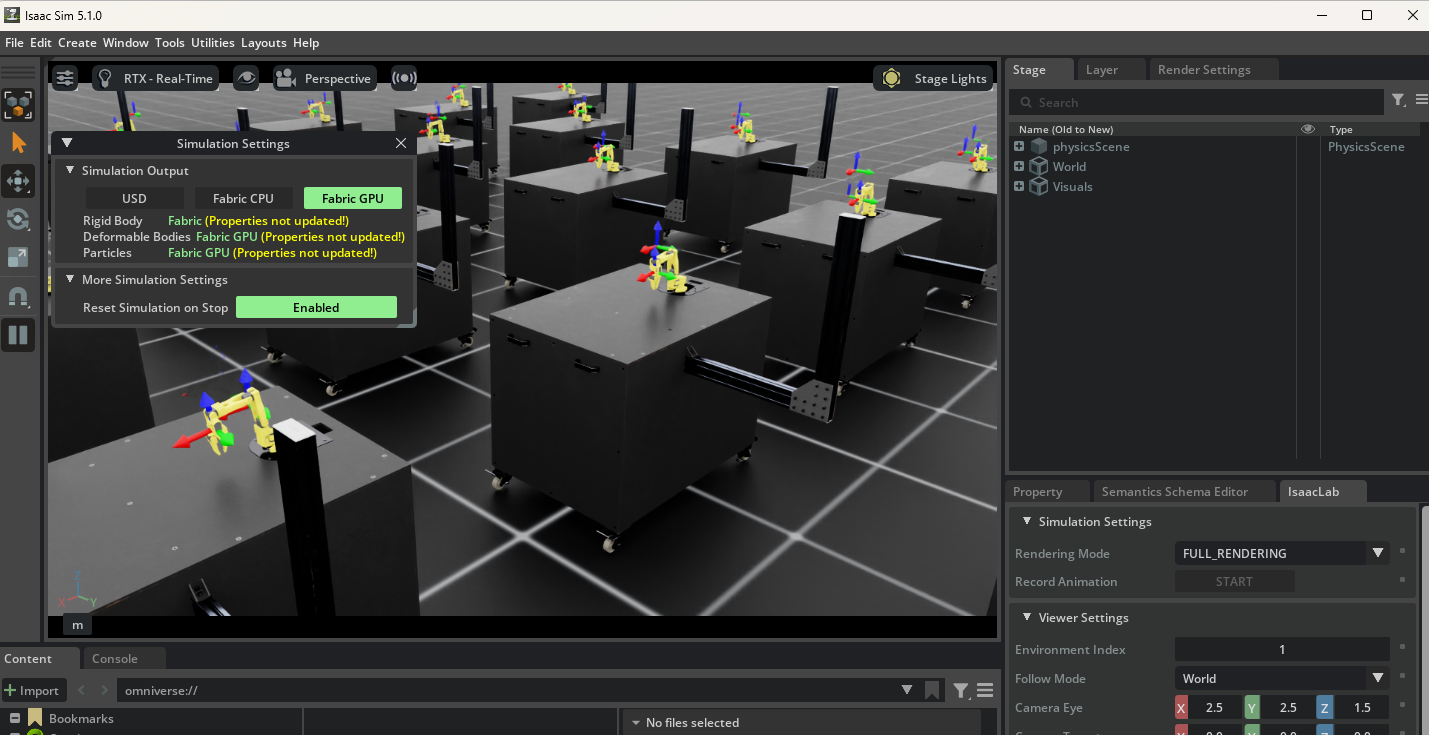

Simulation in Isaac Sim

Why simulate

Testing and training cannot wait until it is built. Making sure there are no design flaws and creating pathing and getting it as crisp as possible are always the goal and isaac sim makes that possible

Real-world testing

Hardware validation

After printing and simulation, I tested the real arm, absolutely so awesome when it worked, but needs tons of work still!